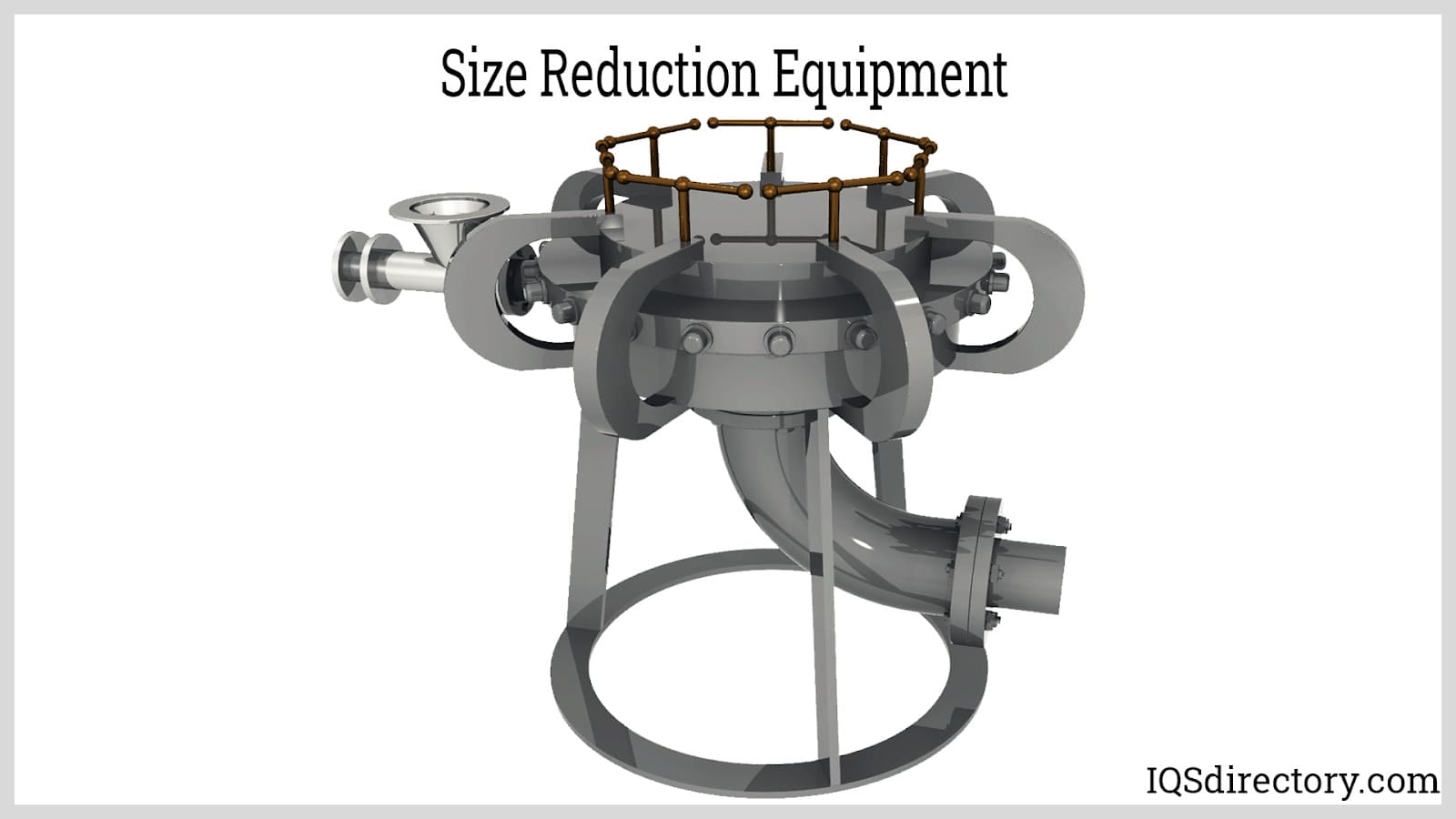

Impact crushers are often used for secondary pulverizing rather than primary pulverizing and are often referred to as impactors as well. Impact crushers can be used on soft, medium-hard and very hard materials, both abrasive and non-abrasive. As a result of the wide range of materials they can pulverize, a wide range of industries make use of impact crushers. Read More…

Here at Granutech-Saturn Systems we manufacture high performance equipment which can handle the toughest projects. Our Saturn Hammermills are engineered to meet the specific requirements of a variety of applications.

SSI Shredding Systems, Inc. is ready to suit your shredding, compacting and pulverizing needs. We have multiple reducers to choose from to meet your pulverizing requirements with ease.

Shred-Tech is an industry leader in the custom design and manufacturing of waste reduction systems and shredding machinery for a variety of recycling applications.

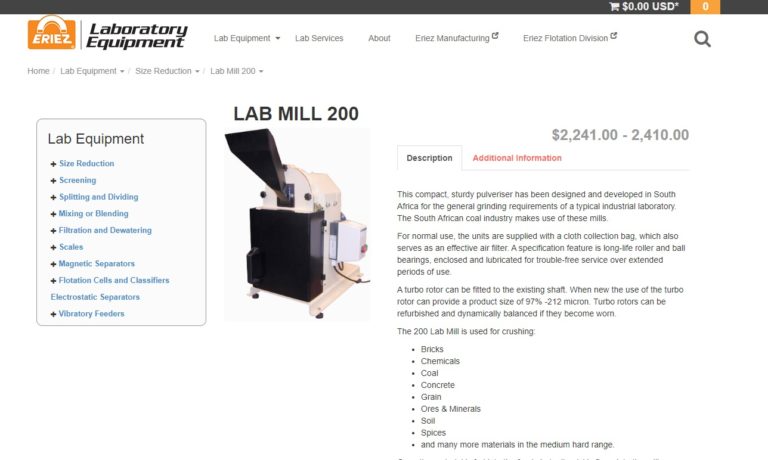

Eriez designs and manufactures pulverizers as well as a wide variety of other size reduction equipment. Our pulverizers can crush coal, chemicals, spices, bricks, soil, and more. We have developed solutions for the food, chemical, mining, and many other industries. If you need to separate your products or materials efficiently and quickly, call Eriez today!

Crush, grind, granulate, shred, pulverize, de-lump - Whatever material processing you need, TerraSource Global has the equipment you`ve been looking for. Since we first opened our doors, TerraSource Global has provided pulverizers, wood grinders, feed & grain mills, lumpbreakers and custom products to a number of industries. Manufacturing expertise defines our business. Call today!

More Impact Crusher Manufacturers

A few examples are highway construction, for the impaction of building materials and rubble; mining, to impact both mined and quarried materials; industrial manufacturing, to impact various materials for use in further processing such as burning for power generation or easier processing; and recycling, for the impaction of large materials that must be reduced in size before they can be re-used.

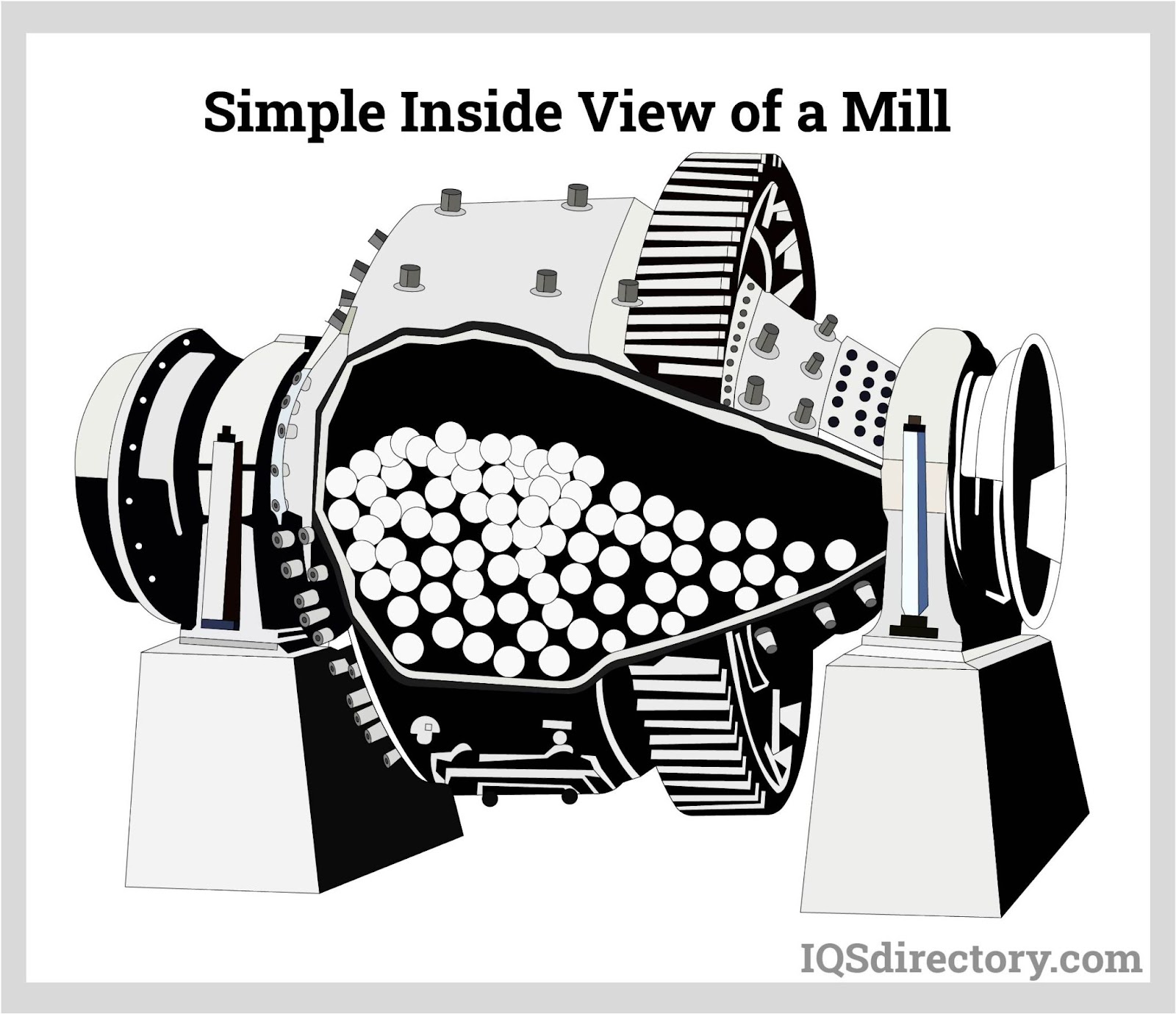

Although the method of pulverizing remains the same, impact crushers can be generally categorized into two main types: horizontal shaft impactors (HSI) and vertical shaft impactors (VSI). The design of a HSI crusher includes three main parts: impeller bars, curtain liners and adjustable liner plates. In a HSI crusher, materials undergo impaction when they reach the breaker-plate, at which point hammers that are fixed to the outer edge of a spinning rotor, are used to impact the material.

HSI crushers can be used for wet or dry materials, but not sticky materials, and are best suited for soft materials such as dolomite aluminum, weathered shale and clay. Although they are similar to HSI crushers, VSI crushers differ in that they feature a high speed rotor as well as a crushing chamber that is much tougher in design.

These additional features are necessary because in VSI crushers, velocity rather than hammers are used for impaction; they involve throwing the materials against hard walls at high speeds. VSI crushers can be further broken down into two more categories: shoe and anvil VSI crushers and autogenous VSI crushers. While both are well-suited for sand and gravel applications, shoe and anvil VSI crushers are better-suited for recycling applications, whereas autogenous VSI crushers are best-suited for quarried materials.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services