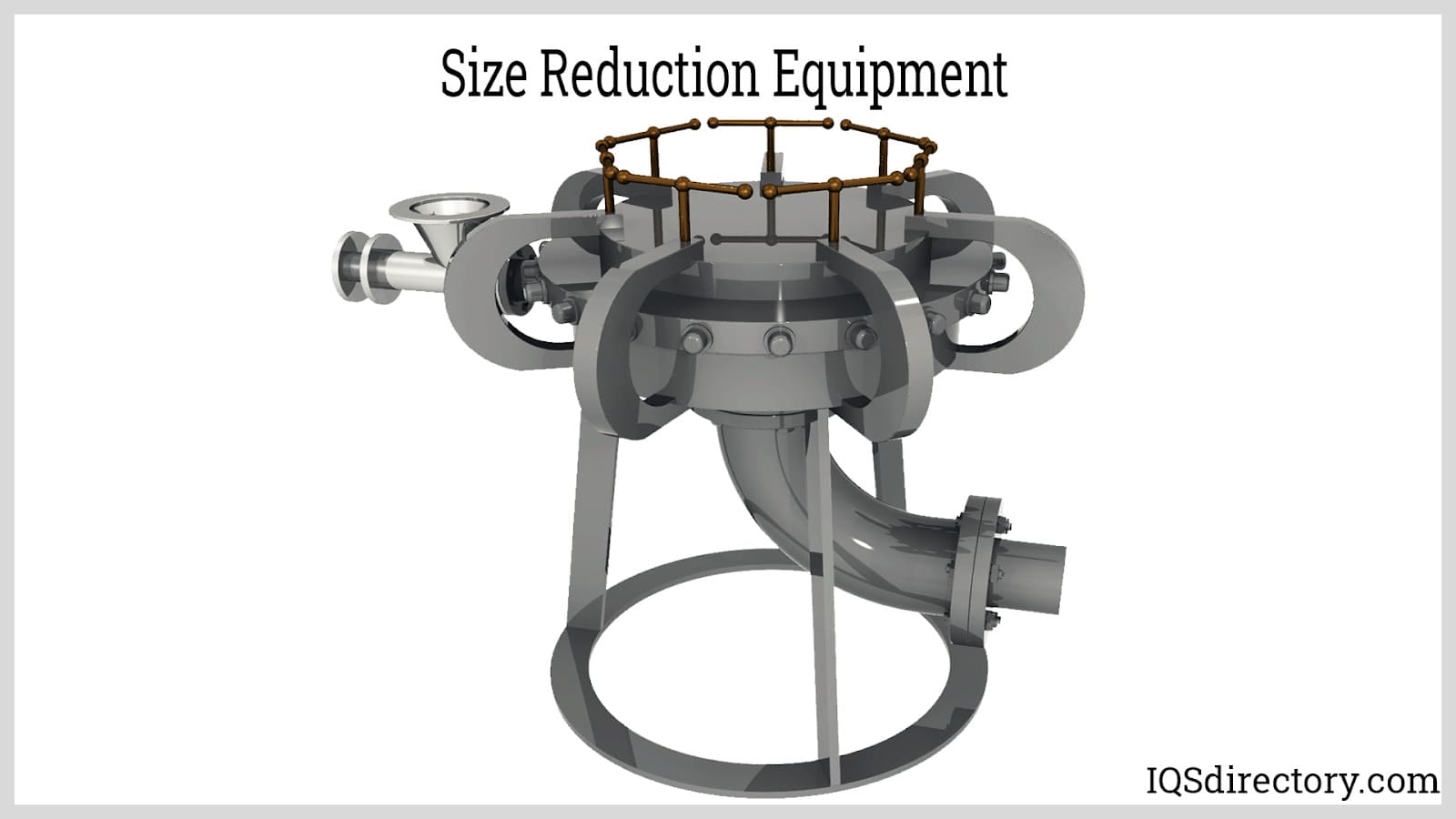

Size reduction is an important part of many industrial processes, making ball mills and other pulverizing mechanisms vital to these industries and in high demand. Particularly in processes that involve the mixing of materials, the smaller the particulate size of the materials to be mixed, the easier and more complete the mixing will be. Ball mills are useful tools for metal alloying processes for this reason; they can crush and grind the constituent materials into very small particles, which makes them easier to combine. Read More…

Here at Granutech-Saturn Systems we manufacture high performance equipment which can handle the toughest projects. Our Saturn Hammermills are engineered to meet the specific requirements of a variety of applications.

SSI Shredding Systems, Inc. is ready to suit your shredding, compacting and pulverizing needs. We have multiple reducers to choose from to meet your pulverizing requirements with ease.

Shred-Tech is an industry leader in the custom design and manufacturing of waste reduction systems and shredding machinery for a variety of recycling applications.

Eriez designs and manufactures pulverizers as well as a wide variety of other size reduction equipment. Our pulverizers can crush coal, chemicals, spices, bricks, soil, and more. We have developed solutions for the food, chemical, mining, and many other industries. If you need to separate your products or materials efficiently and quickly, call Eriez today!

Crush, grind, granulate, shred, pulverize, de-lump - Whatever material processing you need, TerraSource Global has the equipment you`ve been looking for. Since we first opened our doors, TerraSource Global has provided pulverizers, wood grinders, feed & grain mills, lumpbreakers and custom products to a number of industries. Manufacturing expertise defines our business. Call today!

More Ball Mill Manufacturers

Ball mills are also used for the particle size reduction of black powder, cement, fertilizer, silicates and even a variety of ferrous and non-ferrous metals. Ball mills are very similar in design and operating concept to rock tumblers, which used milling media to polish rocks in a rotating cylinder.

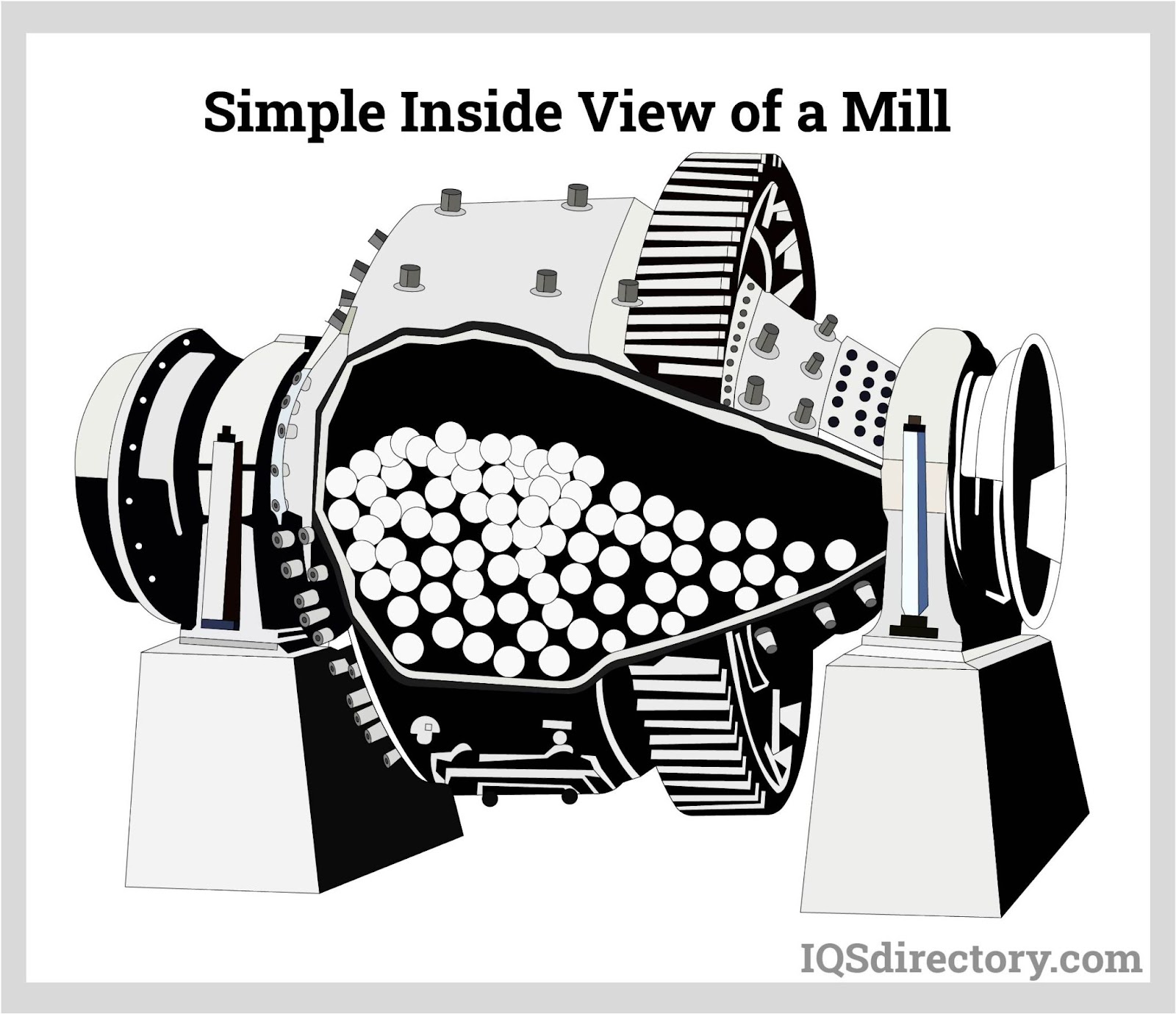

Ball mill machines usually include a cylinder, a motor and crushing media. The cylinder is where the crushing happens. The material intended for crushing is fed into the cylinder along with crushing media. Crushing media can be composed of many materials; a few examples include lead-antimony alloys and steel as well as non-metals like flint and ceramics.

When the crushing media and material to be crushed are combined in the cylinder, the cylinder is rotated by a powerful motor. As the cylinder rotates, the crushing media are thrown about the cylinder, smashing the material to be crushed as they move. After enough time has passed, the materials become crushed into very small particles. Once sufficiently crushed, the materials can be discharged from the cylinder and replaced with new materials to be crushed.

This process can be carried out in batches, or it can be continuous. Continuous ball milling involves the ongoing automatic loading of materials to be crushed and unloading of crushed materials. Depending on the scale of the milling operation, ball mills can be small enough to fit on work benches or large enough to take up entire rooms.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services