There are many different types of crushers, and some of the most widely used types are jaw crushers, gyratory crushers and cone crushers. Jaw crushers and gyratory crushers work well on both soft and hard materials and are often utilized in industries such as mining, for reduction of large quarried materials such as ore; construction, to reduce large building materials such as stone and concrete; and industrial manufacturing, for the processing of large, dense materials. Read More…

Here at Granutech-Saturn Systems we manufacture high performance equipment which can handle the toughest projects. Our Saturn Hammermills are engineered to meet the specific requirements of a variety of applications.

SSI Shredding Systems, Inc. is ready to suit your shredding, compacting and pulverizing needs. We have multiple reducers to choose from to meet your pulverizing requirements with ease.

Shred-Tech is an industry leader in the custom design and manufacturing of waste reduction systems and shredding machinery for a variety of recycling applications.

Eriez designs and manufactures pulverizers as well as a wide variety of other size reduction equipment. Our pulverizers can crush coal, chemicals, spices, bricks, soil, and more. We have developed solutions for the food, chemical, mining, and many other industries. If you need to separate your products or materials efficiently and quickly, call Eriez today!

Crush, grind, granulate, shred, pulverize, de-lump - Whatever material processing you need, TerraSource Global has the equipment you`ve been looking for. Since we first opened our doors, TerraSource Global has provided pulverizers, wood grinders, feed & grain mills, lumpbreakers and custom products to a number of industries. Manufacturing expertise defines our business. Call today!

More Crusher Manufacturers

Cone crushers, which are best-suited for medium to very hard materials, are advantageous for industries, including metallurgical, for the processing of large aggregates supplied by metal mining such as iron and copper ore; road building, for the reduction of building materials such as asphalt and concrete; and chemical, for the reduction of minerals used in chemical processing such as phosphate and silicic acid. Crushers are also used in industries such as demolition, automotive manufacturing and smelting.

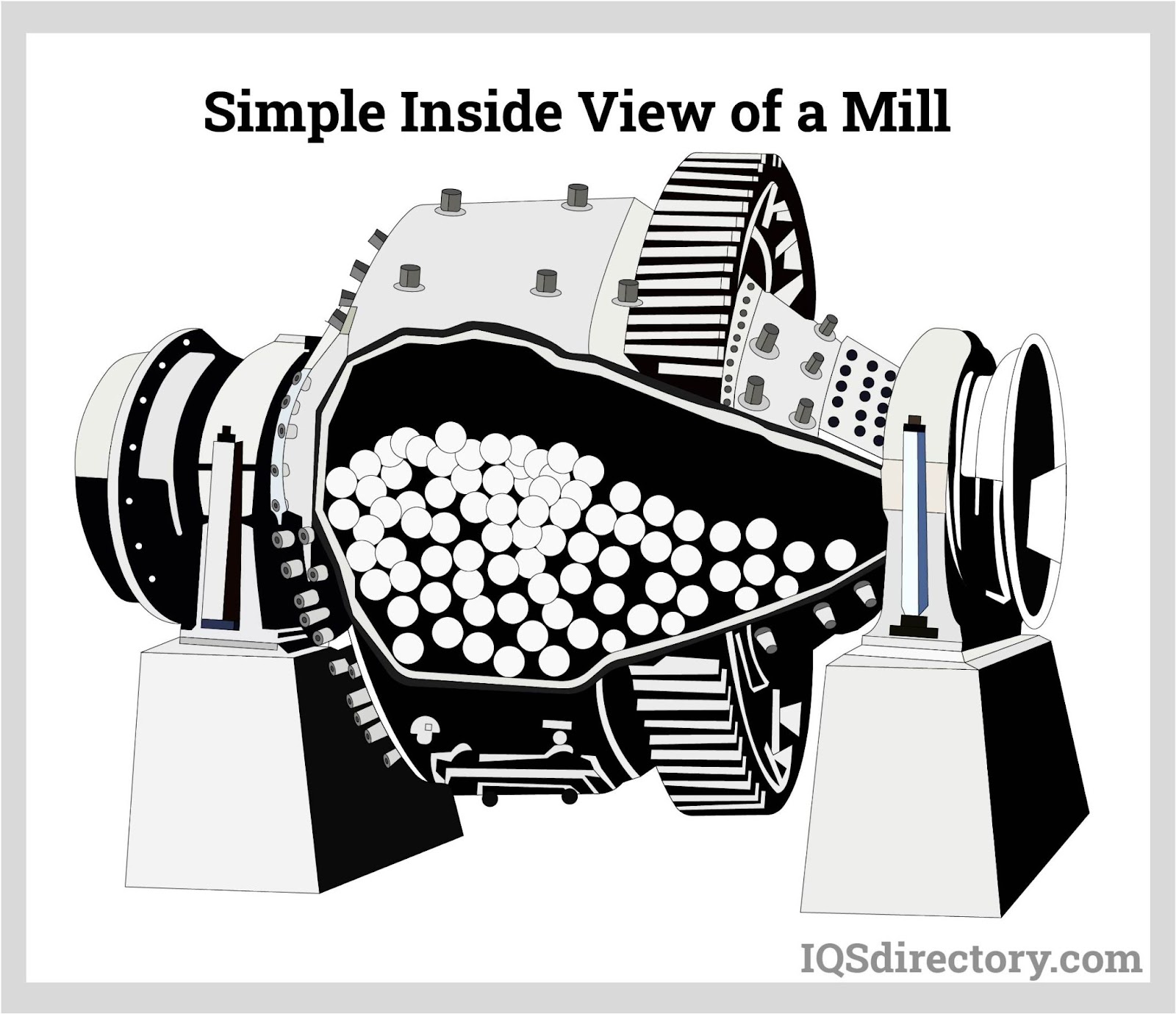

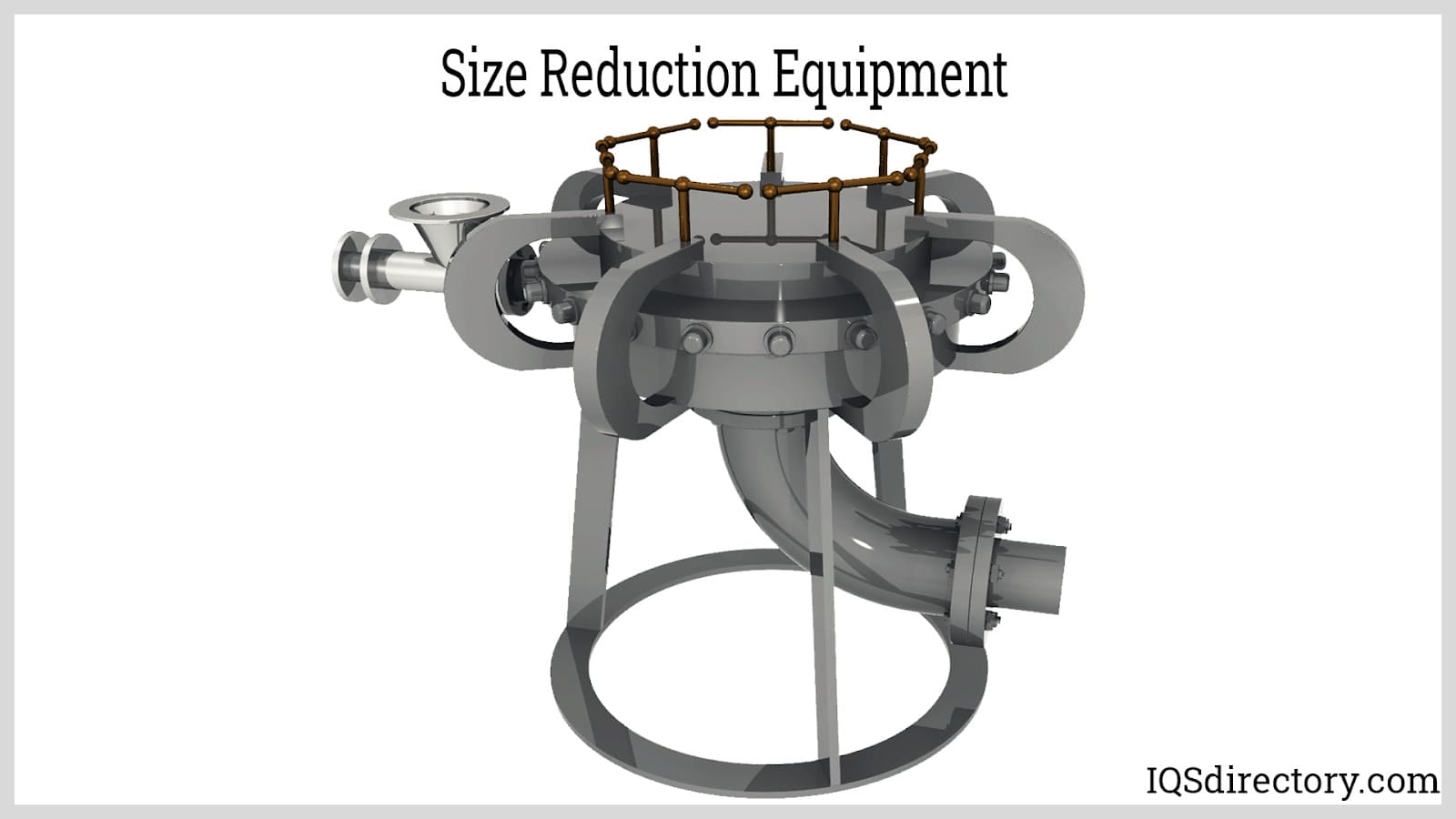

Crushers primarily function to break apart or compress materials as a result of transferring a force supplied by mechanical means through a material that is molecularly stronger than the material it is crushing. Crushers hold materials between two parallel surfaces and then force the surfaces together with enough force to either fracture or deform the material. While they all rely on the same principle of compression, the different types of crushers function in slightly different ways.

Jaw crushers are very easy to spot versus other types of crushers because they have a recognizable design with a set of large vertical "jaws." Of the jaws, one is stationary, while the other is mobile, and its movement creates the energy necessary for compression. Gyratory crushers, while similar to jaw crushers, differ in that they are conically-shaped with a concave surface and conical head. The movement in gyratory crushers is generated through an eccentric arrangement.

Cone crushers, on the other hand, are more similar to a gyratory crusher than a jaw crusher. Cone crushers are even more conically-shaped, with a large top opening for loading the large materials and a much smaller-bottom opening for the much smaller, crushed materials to exit. Typically, cone crushers function by squeezing materials between an eccentrically gyrating spindle and a concave hopper, both of which are protected by wear-resistant materials.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services