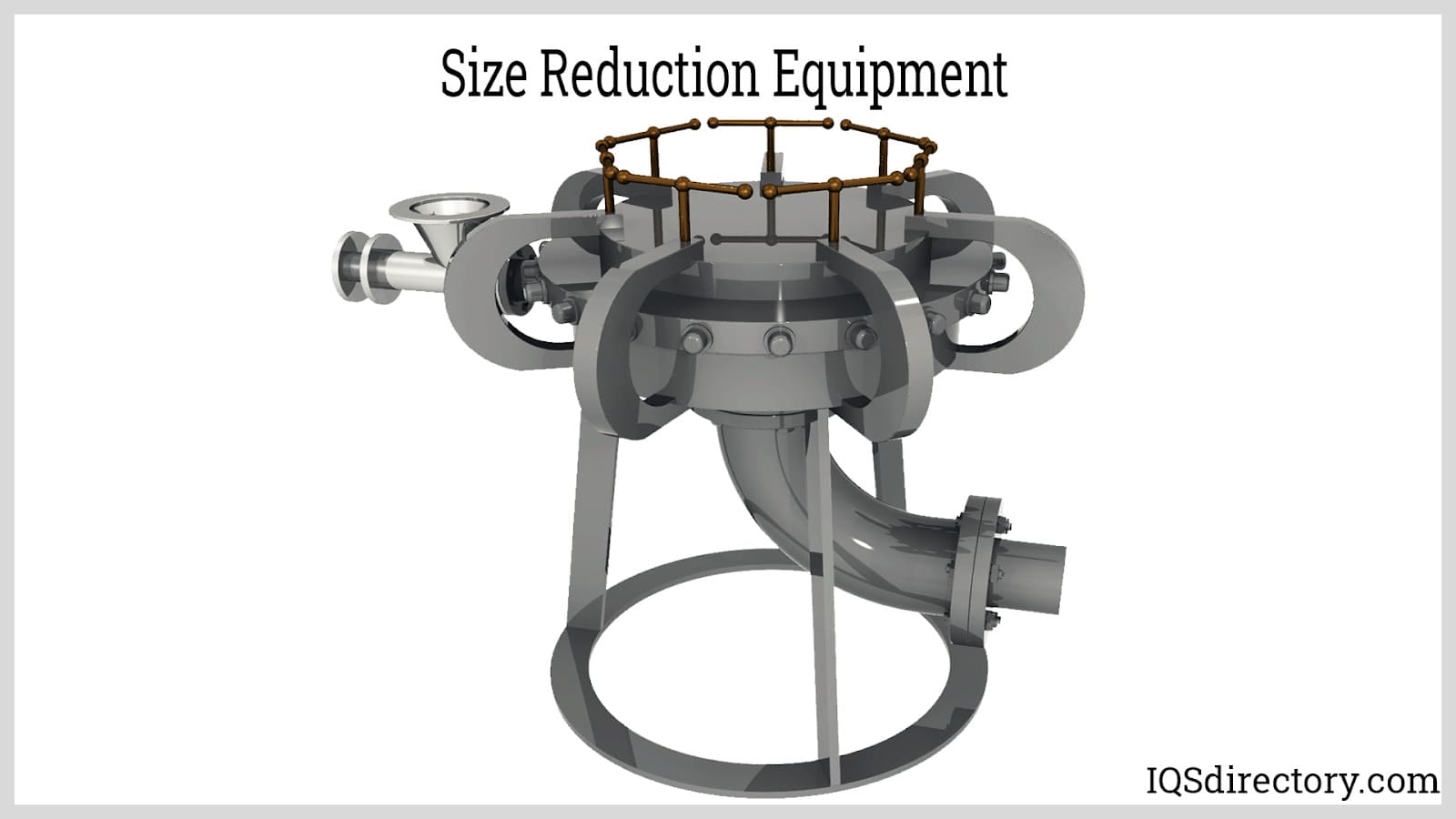

Hammermills are size reduction tools used in industrial waste disposal, raw material processing and many other operations. Size reduction tools are important parts of many industrial processes. Because the variety of materials that are processed by size reduction equipment is so wide, an equally wide variety of equipment is necessary to accommodate them. Read More…

Here at Granutech Saturn Systems we will provide you with the top of the line hammermills and our experts will work with you to find the perfect solution for your application. We offer a number of solutions including hammermills, crushers, loggers, heavy-duty shredders, grinders, granulators, powderizers, and refiner mills. Our hammermills have an 200hp motor and utilize a heavy duty steel...

SSI Shredding Systems, Inc. is ready to suit your shredding, compacting and pulverizing needs. We have multiple reducers to choose from to meet your pulverizing requirements with ease.

Shred-Tech is an industry leader in the custom design and manufacturing of waste reduction systems and shredding machinery for a variety of recycling applications.

At Eriez, our hammermills can be designed for reduction of medium hard to hard friable materials, such as coal, hard chemicals, wood chips, and more. Our MACSA Impact Hammermill features a dynamically balanced rotor that comprises of six replaceable hard-faced swing beaters mounted on swinger plates. The mill housing is fully lined. It is also available in standard and 300 x 300 configurations....

Crush, grind, granulate, shred, pulverize, de-lump - Whatever material processing you need, TerraSource Global has the equipment you`ve been looking for. Since we first opened our doors, TerraSource Global has provided pulverizers, wood grinders, feed & grain mills, lumpbreakers and custom products to a number of industries. Manufacturing expertise defines our business. Call today!

Hammer Mills – International Process Equipment Company

Hammer Mills – International Process Equipment Company Hammer Mills – International Process Equipment Company

Hammer Mills – International Process Equipment Company

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services