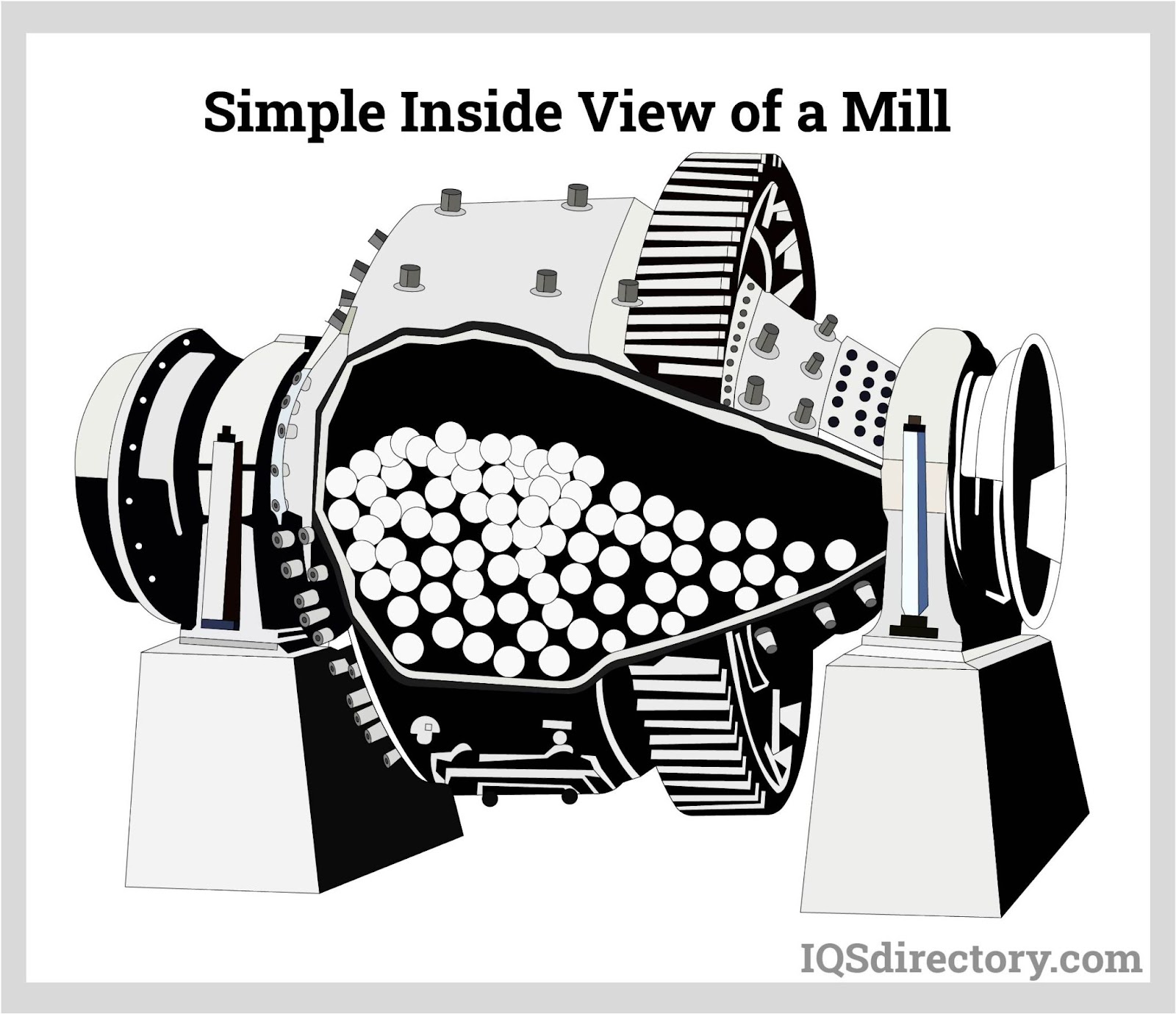

Granulators generally have an open rotor configuration which means that air can easily move around the rotor while cooling the product however there are also closed rotor granulators which operate with high speeds. The components are typically ground down to the consistency of corn meal and sometimes even smaller. These grains range from 0.2 and 4.0mm. Read More...

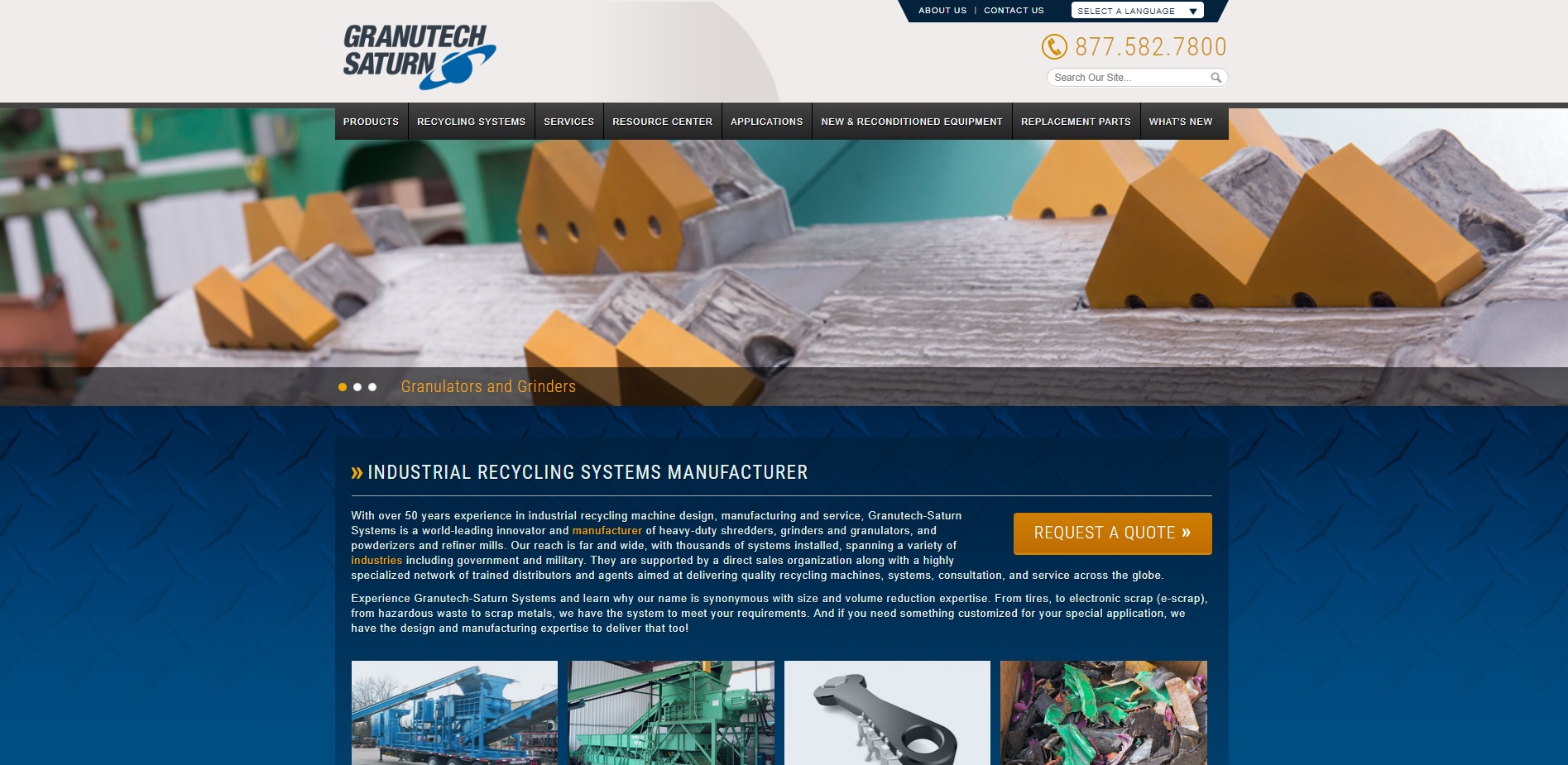

Granutech-Saturn Systems

Here at Granutech Saturn Systems we will provide you with the top of the line granulators and our experts will work with you to find the perfect solution for your application. We offer a number of solutions including hammermills, crushers, loggers, heavy-duty shredders, grinders, granulators, powderizers, and refiner mills. Our granulators have an 200hp motor and utilize a heavy duty steel housing. These high powered machines can handle different types of materials and can process four tons an hour. We also offer a full range of secondary services if your application requires. We have over 50 years of industry experience and we strive to develop the latest innovations in our field. Our products are thoroughly tested and guaranteed to last for many years to come.

Grand Prairie, TX | 877-582-7800

Request for Quote

More Granulator Manufacturers

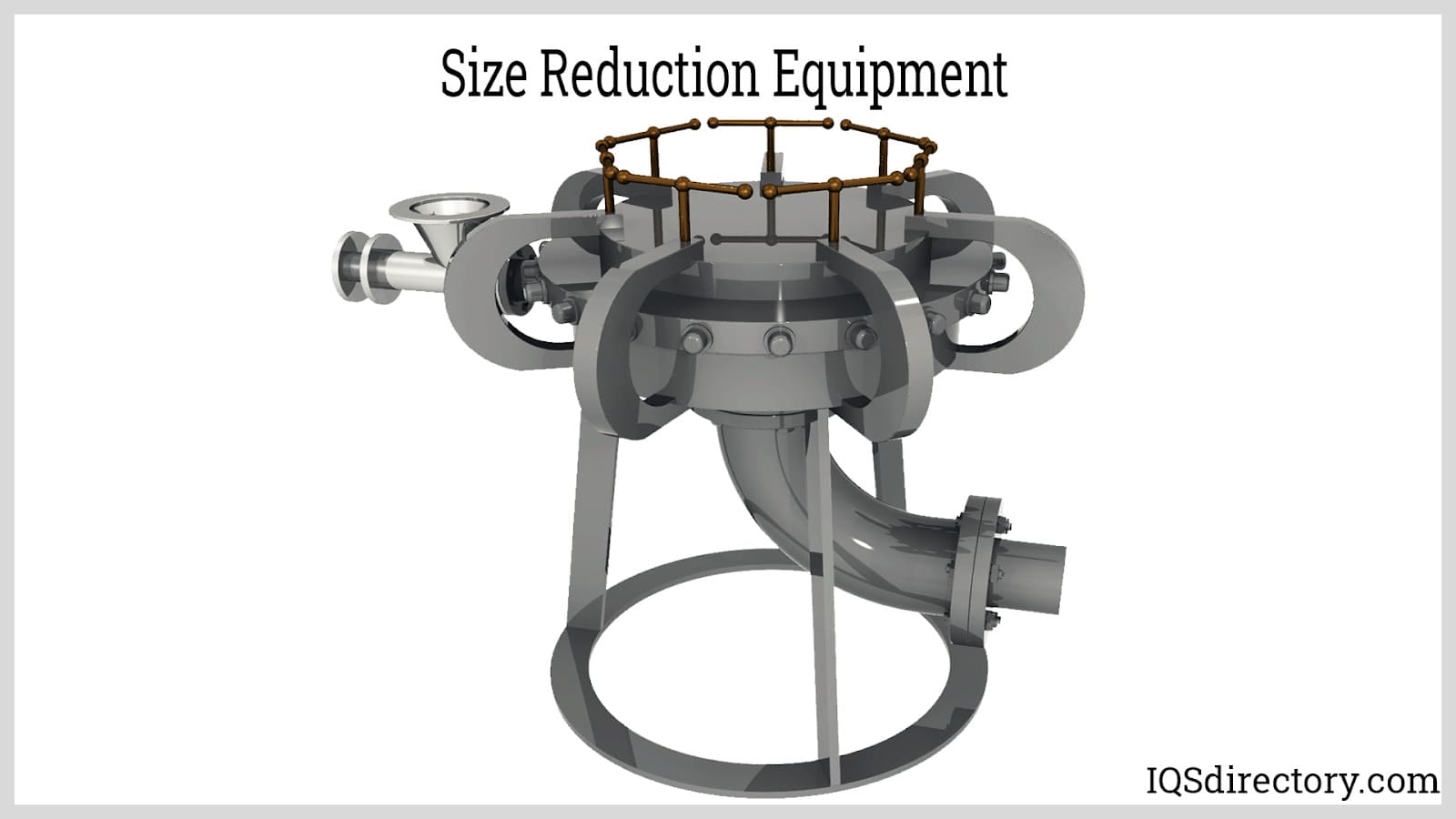

There are two types of granulation which are wet granulation and dry granulation. Wet granulation causes the granules to be formed when the granulation liquid is pour onto a powder bed and is mixed together through a impeller, screws, or air. The agitation of the two substances creates the wet granules.The most common liquids included are water, ethanol, and isopropanol. Aqueous based solutions are generally much safer to handle than solvent based solutions.

Dry granulation is when the granules are formed without the use of a liquid. This process is prefered in situations where the products may be sensitive to moisture and heat. To create these granules without the utilization of moisture will require the use of a compactor. Granulators are very important for various applications involved in the recycling industry. These products are ideal for lighter materials like plastics and rubber as these substances do not grind well.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services